|

SOFTLIFE MATTRESS MACHINERY CO.,LTD

|

Gold Index: 116543

You are here: home > Foaming machine > Continuous sponge production line

Continuous sponge production line

| Price: | 130000.0~160000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

SL-08FC-1

Production Capacity:

100SETS

Delivery Date:

50 DAYS

Foaming head:

Trough foaming /Spray foami...

Chemical group:

12 groups

Foaming type:

Horizontal foaming

Max output:

250kgs/min

Means of Transport:

Ocean

Packing:

EXPORT PVC FILM

Brand Name:

SOFTLIFE

Foaming mode:

Continuous

Control system:

Computerized control

Flat top control:

Falling plate

Total power:

71KW

automatice control foaming machine can make pu foam density from 9--50kgs/m3, can calculate formula automatic

CNC Continuous Foaming machine

The machine is mainly suitable for density of 9 - 50KG/M3 soft polyurethane foam continuous production, according to customer requirements and automatic cut into different size block. The machine also increases the safety door and window on both sides, increase the safety observation channels on both sides. The entire production process in full digital control, accurate, convenient. The operation is more simple and reliable.

Computer control system: the entire production process in full digital control, the huge equipment more humane, so the operation is very simple, clear; production formula can be unlimited deposit.

Automatic formula function: input from an operator to a desired density color, automatically generated reference formula feeding, automatic calculation. If the customer input feeding, automatic calibration formula correctness.

Cost accounting functions: automatically gives each foaming material consumption, yield. Electronic measurement systems: from the United States advanced electronic metering pumps and electronic monitoring device consists of the measurement system, the 12 group of chemical material formula and the actual supply both graphically and numerically by computer for two kinds of direct readout. When the actual supply and formulations do not meet the requirements, measurement system will be automatically adjusted, with high accuracy. It is to produce a good soak cotton and reduce unnecessary loss of materials to lay the foundation.

High speed stirring system : the practice of two stage low pressure high speed stirring, pore delicate uniform; and circulatory cooling and automatic cleaning function.

Automatic cutting system: computer control, can change the cutting length, precision≤ 1mm

Automatic constant temperature device ( optional): control of material temperature, to produce high quality foam.

Flat control system (this is optional equipment ( R.S ): Film Pulling Unit ) improve foam on top of the smoothness, utmost ground reduces foam scrap rate.

Main technical parameters:

The machine is mainly suitable for density of 9 - 50KG/M3 soft polyurethane foam continuous production, according to customer requirements and automatic cut into different size block. The machine also increases the safety door and window on both sides, increase the safety observation channels on both sides. The entire production process in full digital control, accurate, convenient. The operation is more simple and reliable.

Computer control system: the entire production process in full digital control, the huge equipment more humane, so the operation is very simple, clear; production formula can be unlimited deposit.

Automatic formula function: input from an operator to a desired density color, automatically generated reference formula feeding, automatic calculation. If the customer input feeding, automatic calibration formula correctness.

Cost accounting functions: automatically gives each foaming material consumption, yield. Electronic measurement systems: from the United States advanced electronic metering pumps and electronic monitoring device consists of the measurement system, the 12 group of chemical material formula and the actual supply both graphically and numerically by computer for two kinds of direct readout. When the actual supply and formulations do not meet the requirements, measurement system will be automatically adjusted, with high accuracy. It is to produce a good soak cotton and reduce unnecessary loss of materials to lay the foundation.

High speed stirring system : the practice of two stage low pressure high speed stirring, pore delicate uniform; and circulatory cooling and automatic cleaning function.

Automatic cutting system: computer control, can change the cutting length, precision≤ 1mm

Automatic constant temperature device ( optional): control of material temperature, to produce high quality foam.

Flat control system (this is optional equipment ( R.S ): Film Pulling Unit ) improve foam on top of the smoothness, utmost ground reduces foam scrap rate.

Main technical parameters:

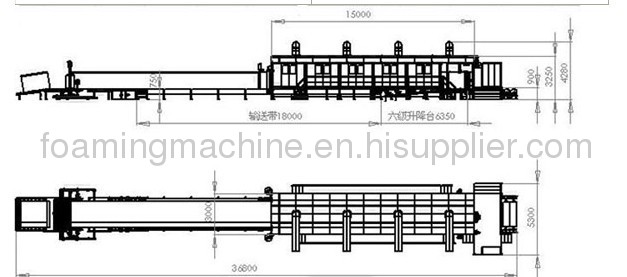

Material science | ≤12Group |

Discharging form | Move head or an overflow groove in 2 ways |

Mixing speed | ≤5000rpm/min |

Length of oven | 12.5m |

Lifting platform | 6 level 6.25m |

Conveyor belt | 18 m |

Sponge width | 1.3m – 2.25m |

Foam height | ≤1.25m |

Production rate | ≤8 m/min |

Maximum output | 250kg/min |

Total power | 70.85kw |

The appearance of the complete machine | 38m *4.5m (long ) ( W) *4m ( high ) |

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Production Line

Pipe Production Line

Cement Production Line

Beverage Production Line

Board Production Line

Foam Production Line

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

SOFTLIFE MATTRESS MACHINERY CO.,LTD [China (Mainland)]

Business Type:Manufacturer

City: Jiangmen

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Product (990)

- Foaming machine (172)

- Foam cutting machine (150)

- Mattress machinery (163)

- Auto conveyors and other (152)

- Others (353)